company overview

Castle was born from the vision of two Irish carpenters, Graham Owens and Kevin Maher. With a shared passion for craftsmanship and a bold entrepreneurial spirit, they founded Castle, a small-scale façade, cladding and metalworks installer company, in Melbourne in 2019.

Today, Castle is renowned for its high-quality manufacturing services, delivering unparalleled cladding and metalwork solutions to multi-million-dollar projects across various sectors in Victoria.

Click to discover moreWe have a state-of-the-art facility in Braeside, Melbourne, dedicated to delivering exceptional manufacturing services.

Our 1750m² factory floor is designed for seamless workflows and houses advanced equipment, including a waterjet, laser cutter, two CNC routers, two welding bays, multiple assembly benches, and two brake presses. Additionally, our in-house powder coating department enhances our ability to deliver high-quality finishes. Trust us to deliver exceptional solutions for any project, large or small.

Whether you’re looking window shrouds or a full façade, our tailored solutions cater to architectural, commercial, and industrial clients across Australia. Our services ensure high-quality finishes and functional enhancements, making your investment in cladding a lasting one.

With over 40 years of combined industry experience, our directors, Kevin Maher and Graham Owens, lead with unmatched expertise. Their background in carpentry, facade installation, and project management ensures that every project benefits from a wealth of knowledge and skill.

At Castle, quality is our cornerstone. We surpass industry benchmarks through meticulous attention to detail, cutting-edge technology, and a steadfast commitment to sustainability and safety.

We do everything from design and development to manufacturing and installation, eliminating the hassle of coordinating with multiple contacts for a single project. Our integrated approach gives you an end-to-end service, aligning seamlessly and enhancing efficiency.

Adhering to detailed schedules and maintaining proactive communication guarantees that every project is completed on time, within budget and to the highest standards. We make sure to realise your exact vision.

Our process

A smooth process is essential for any successful construction project. We keep our focus on precision, efficiency, and quality throughout every stage. Here are 5 simple steps to our approach.

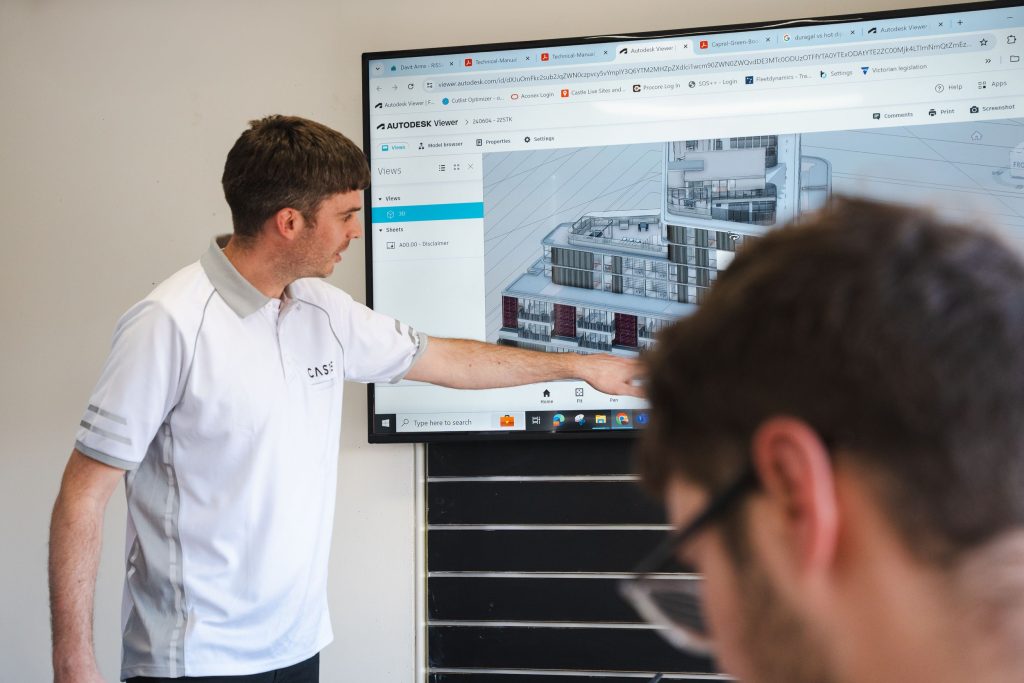

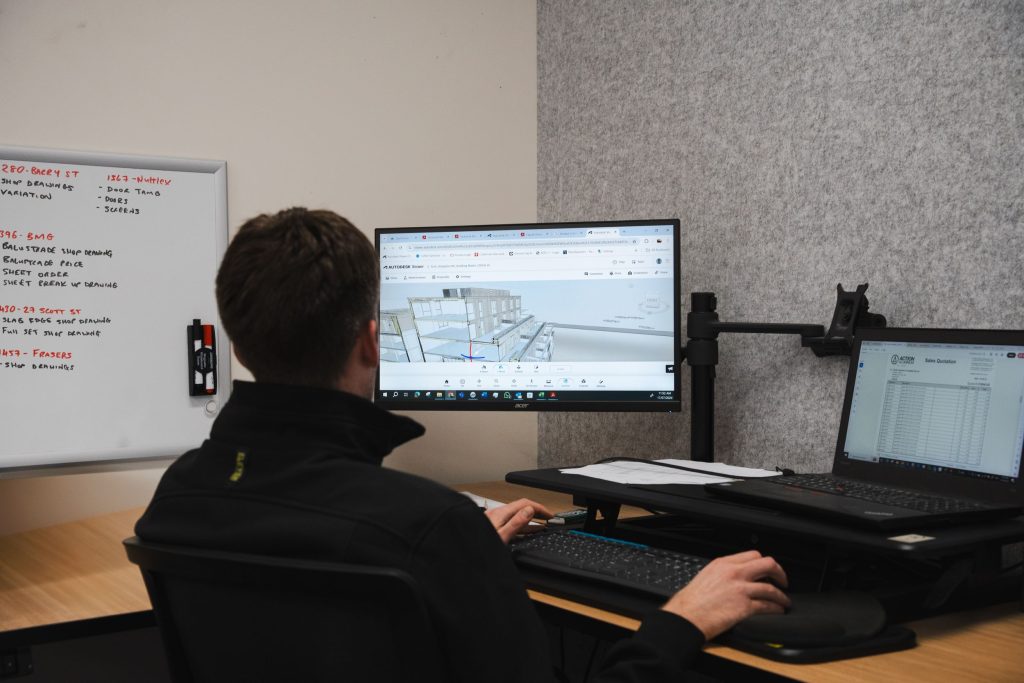

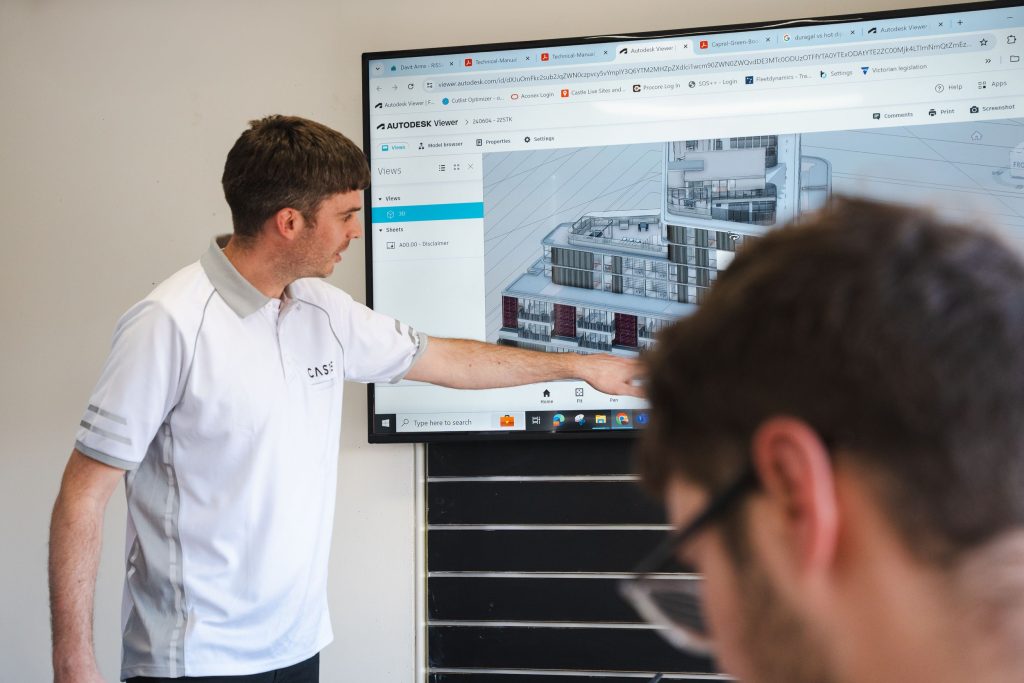

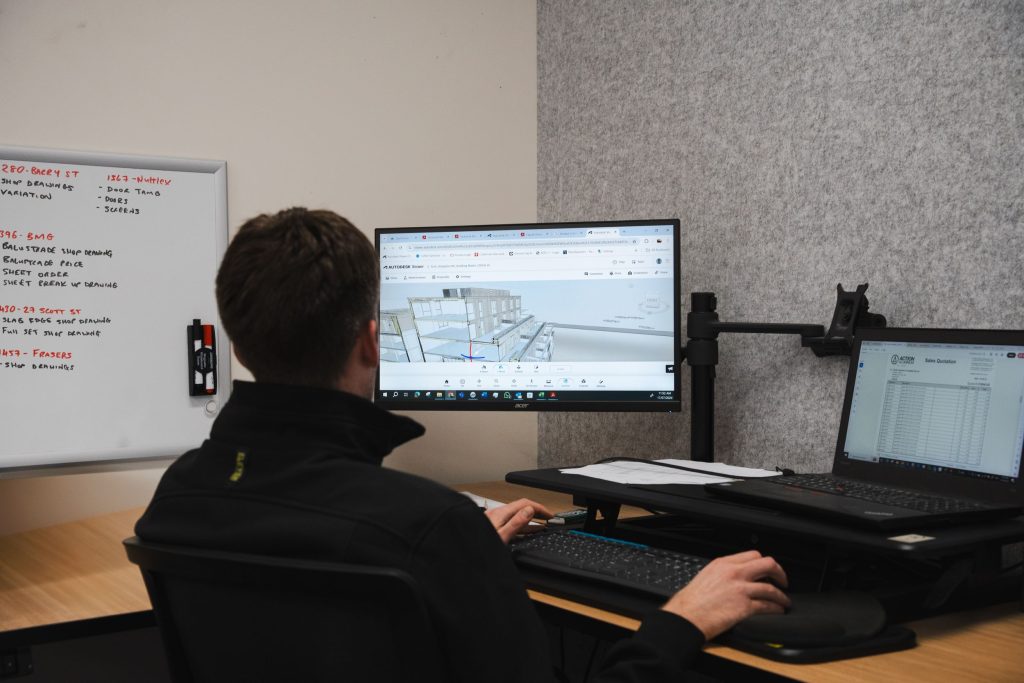

Click to discover moreUsing advanced BIM/CAD tools, we create detailed plans and blueprints that perfectly capture the image in your head. We thoroughly analyse materials, labour, and timelines to provide you with a transparent estimate that aligns with your budget without compromising quality.

Before the full-scale construction begins, we do a round of prototyping to refine the designs and make changes to address potential issues, saving costs down the line.

From sourcing high-quality materials to advanced fabrication techniques, we work with trusted suppliers across Australia to maintain material excellence and reliability.

We are committed to achieving ISO 9001 certifications, we perform quality assurance tests on every product before it leaves the factory, ensuring they are defect-free. Each panel that leaves our facility is marked with our quality assurance label.

Our dedicated delivery fleet ensures the safe transportation of all project components. With efficient logistics and a commitment to precision, our installation team delivers and installs products with the utmost care, guaranteeing client satisfaction.

Our people

We would not be who we are without our exceptional team working relentlessly behind the scenes. Here’s a bit about them.

Click to discover moreDirector / Project Manager

With over 18 years of carpentry experience across England, Ireland, and Australia, Kevin has a proven track record in high-end projects, including the King’s Cross studios in London. Since co-founding, he has overseen all operations and ensured seamless execution from design to installation.

Director / Project Manager

Graham brings 20 years of carpentry experience and a decade of specialising in facades. His background includes supervising major projects like the Rod Laver Arena. As co-founder and project manager, he excels in building successful teams and developing processes.

Production Manager

As production manager, Cian’s background in chemistry and pharmaceuticals, combined with his experience in machine operation and production management, is crucial for our success.

Pre-construction Manager

With extensive qualifications in construction management, our pre-construction manager, Mike, streamlines project lifecycles by estimating, designing, and overseeing on-site activities, ensuring compliance and enhancing project efficiency.